Belt Conveyor Ovens – MGC103 & SGC103

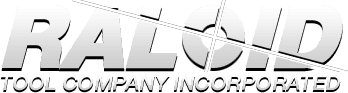

Friction Material Manufacturing Albany, NY

The Raloid Conveyor Ovens are ovens designed specifically for use in the bonding of friction materials. These ovens utilize natural gas, propane, or oil (depending on the model) to fire a positive pressure burner and generate the required heat. The heat is regulated by a Digital Temperature Control which cycles the burner as required to maintain the optimum oven temperature.

All Raloid Conveyor Ovens have their conveyor speed infinitely adjustable. This enables setting the speed for the size shoe clamps in use. The MGC103 has a capacity of 360 shoes per hour, or 2880 shoes per 8 hour shift. The SGC103 has a capacity of 180 shoes per hour, or 1440 shoes per 8 hour shift.

Outstanding Features common to the SGC103 and the MGC103 include:

1. A mesh conveyor that will accept any clamping system.

2. A custom forced air barrier with flame safety.

3. A solid state Digital Temperature Control.

4. Energy saving end curtains.

5. 2 inches of high temp insulation with metal retaining mesh for low heat loss.

6. Galvanized double wall laminated sides and rigid 2 X 2 frame for durability.

7. Infinitely variable speed conveyor is standard.

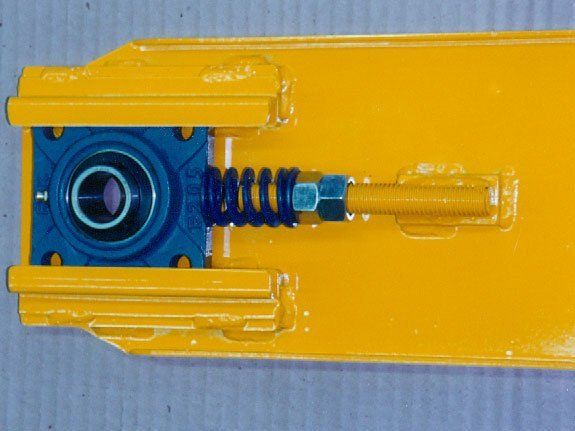

8. Greaseable conveyor bearings – no bushings.

9. Self-adjusting conveyor tensioners.

10. Exhaust stack on oven exit.

11. Easily removable burner and conveyor units for ease of maintenance.

12. Options are available.